Industrial design combines the realms of art, science and engineering - elegant form is functional, practical durability is refined and objects designed for everyday use should be intuitive, ultimately to the point of invisibility. True industrial design adds value - increased functionality, reliability, ease of use and reduced manufacturing costs - these are all results of the fully implemented industrial design process.

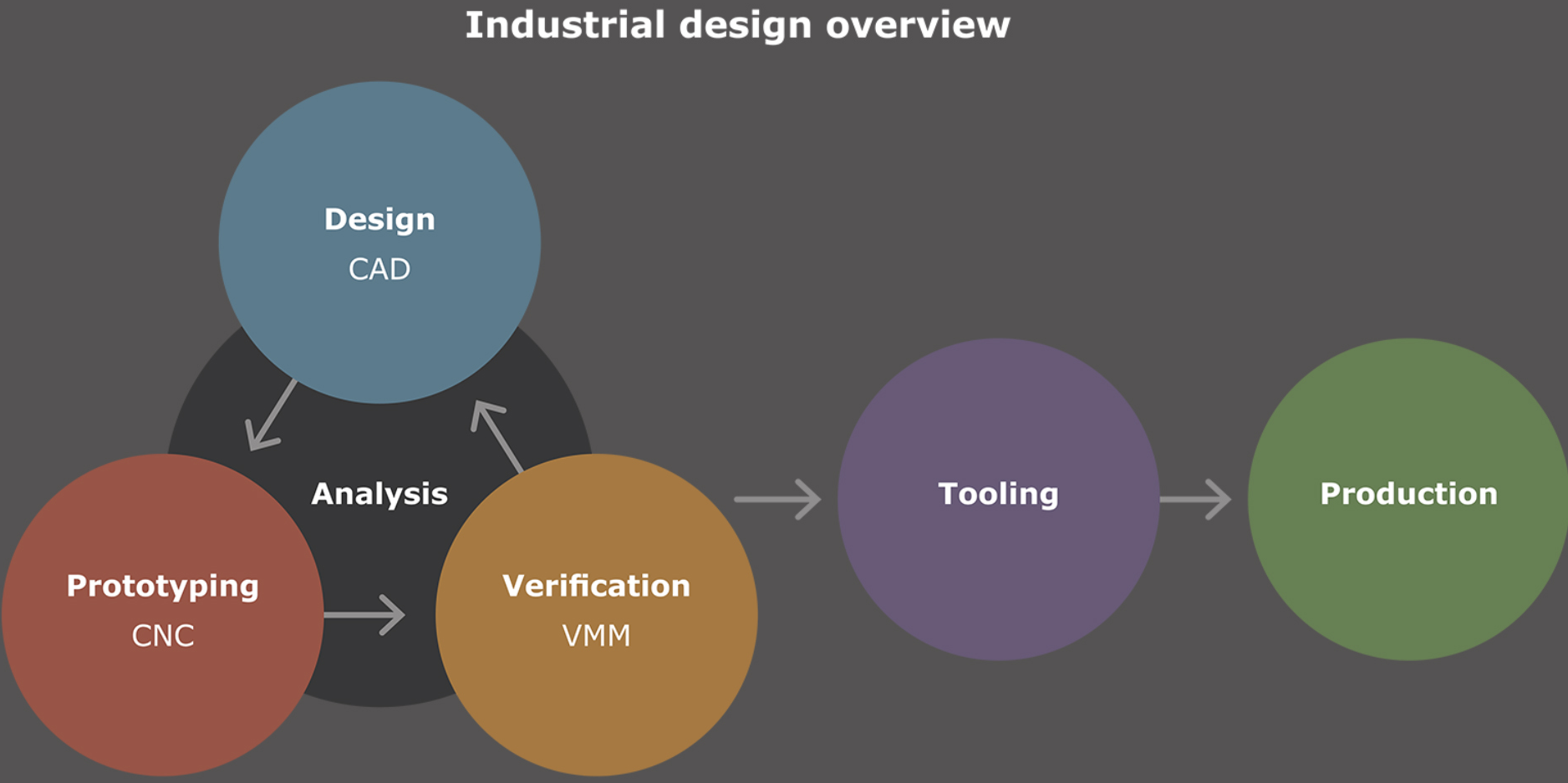

Product design is an integral part of this process - ARID provides both product and industrial design in tandem - product design is creating functional, aesthetically appealing solutions; industrial design is finding the most efficient, cost effective method(s) of manufacturing those solutions, through to delivery to the end user. When the design process is undertaken as part of the industrial design process - that is, from the outset, with the knowledge and experience of how the design will be manufactured, the result is invariably a higher quality, more effective, more reliable product, produced at a lower cost - this is the foundation of ARIDs philosophy and approach to design and production.

ARID has over 25 years experience in product and industrial design and commercialisation, and with more than 300 products developed and taken to market, is proficient at providing solutions and all related services for manufacturing industries Australia-wide, with a growing number of international customers. We provide design and ongoing development and manufacturing solutions for products that can vary from a single plastic part to complex systems requiring hundreds of assemblies and thousands of precision elements, for customers who vary from single inventors to international corporations.

ARID has extensive experience in product design and commercialisation strategies, a vast knowledge of and ‘hands-on’ experience with fabrication materials and manufacturing solutions, and we offer a full range of services including prototyping, in-house short-run production and ongoing mass production, supervised and supported by our own quality control and production assembly facility in Shenzhen, China, with the result that Andrew Rogers is now a multi-award winning designer and named in over a dozen design patents.

ARID can also provide invaluable advice on strategic funding and crowd funding.

Andrew Rogers, Principal Designer, achievements and experience include:

“I will always provide you with the best design solution - it may not be the

solution you were expecting, but it will be the best.” Andrew Rogers

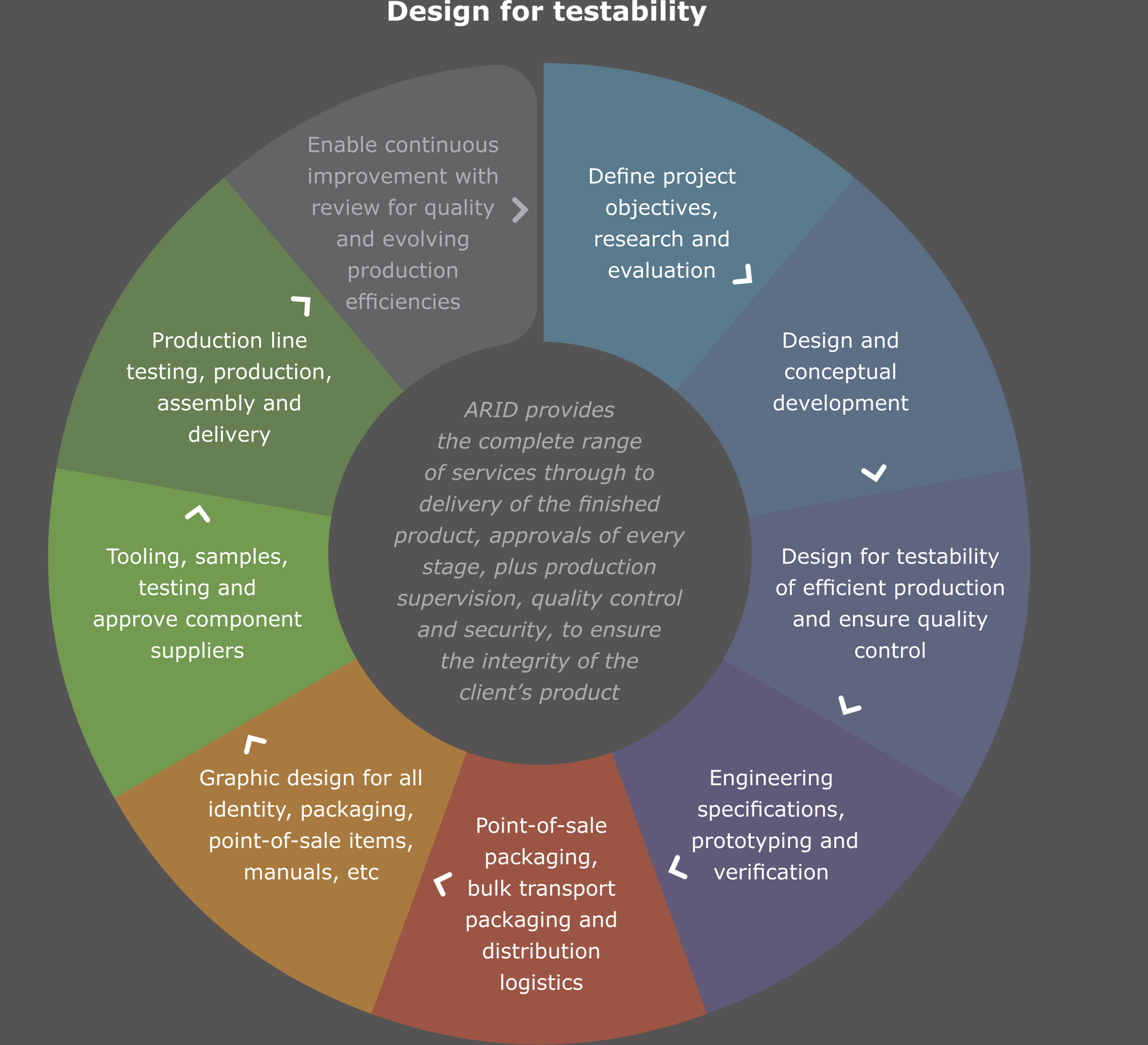

Design for manufacture and testability are crucial aspects of the design process - while most understand design for manufacturing, many overlook the need of design for testability. Design for testability means that the designer knows how to test that a product is optimally functional - to be able to prove through testing, during the manufacture and assembly process, that every component is maximally effective and fully complies with the specifications. Design for testability and strict quality control are a standard part of ARIDs design process, ensuring that each unit produced is of the highest standard.